"2017 Step by Step New Technology Seminar" Shenzhen Station was held on March 31, 2017 from 9:00-17:00 in Jade Hall 2 & Diamond Hall and Crystal Hall on the fourth floor of Jade Store of Shenzhen Shengtosha Hotel. This seminar was sponsored by Hong Kong Yashi International Business News. And by its "SMT China surface Assembly Technology" magazine to do the main promotion media, attracted more than 600 SMT industry technical elites, the vast majority of which are senior executives. Outside the conference room, the booths of more than 30 enterprises are orderly distributed, and what are displayed here are the cutting-edge technology products of enterprises, representing the exploration direction and the latest achievements of the industry.

?

Guangdong Zhongshi Metal Co., Ltd. is one of the sponsors of this seminar.

?

?

19 presentations will be held simultaneously in three conference rooms

?

Among them, conference room A focused on "smart factory and advanced electronics manufacturing process" :

Li Xiaolei, general manager of Shenzhen Sonda Company, explained how "steel mesh information management system" makes material management more efficient;

Zhao Kai, Sales Manager of Mycronic South China Region, shared the new blueprint of Mycronic Industry 4.0 on site;

Gong Bin, Product Manager of Tianjin LPKF, gave a speech on the theme of "Laser precision machining in the electronics assembly industry";

Nordson EFD Greater China Technology Application Manager Feng Shaoxu talks about "Typical Precision Fluid dispensing applications in consumer electronics";

Li Xingjun, Project director of Dongguan Donghe Company, gave a speech focusing on supply chain outsourcing services and introduced MRO industrial product operation solutions.

Wang Junzhao, R&D center manager of Shenzhen Meisin Testing Company, brings unique analysis and insights into the reliability of lead-free solder joints.

?

In-depth discussion of PCBA process in Conference Room B

?

Kuri Nishimura, general manager of Shanghai Spelia Trading Company, led the attention to "SN100CV, a lower cost lead-free silver solder that can replace SAC305 alloy";

Zhou Yun, technical vice president of Shenzhen Tengsheng Company, shared "How to solve the problem of dispensing and inspection process in mobile phone parts."

Mr. Chen Wei, General Manager of ESha Asia Pacific, explained "Selecting Welding Process and Technology";

Yunhong Yu, Electronic Components and Product Application Manager, Asia Pacific, Liquefied Gas China Investment Corporation, spoke on "Application of nitrogen inert protection in PCBA Production";

Wu Dong, manager of the service department of Xiamen Stech Company, analyzed "SPI's impact on the printing process";

Chen Changke, Technical director of MTU Optoelectronics Co., Ltd. vividly elaborated "the application and prospect of machine vision in smart factories and advanced electronic manufacturing processes";

The topic of Mr. Yuan Liu, Business manager of Dongguan Anda Automation Company, was "Application process and solution of PCBA Three anti-coating and dispensing."

?

Conference Hall C is different from the above two halls, this is the "brainstorming" of heavyweight corporate guests

?

Esha Asia Pacific General Manager Chen Wei discussed "reflow and welding theory" here;

Mr. Xue Guanghui, technical consultant of SMT China Magazine, talked about "the world's advanced electronic manufacturing technology and application", hoping to give the participants some new inspiration;

Then Luo Ran Fei of Keenshi took up the topic stick and analyzed "the application of 3D visual inspection in automotive electronics" from the practical experience of the enterprise.

Last but not least, a special foreign technical expert, TOSHIYUKI SUGIYAMA, a member of the Japanese Technical Association of Omron Automation China, discussed the topic of "Vehicle quality operation and installation Sensing trend". He crossed the language barrier and deeply communicated with everyone.

In this seminar, Guangdong Zhongshi Metal Co., Ltd. in the strong support of general Liang, the business department sent a strong sales elite to the venue and exhibition area, in the booth, our sales elite and came to participate in the seminar on the company's products and technology to do a detailed introduction.

?

?

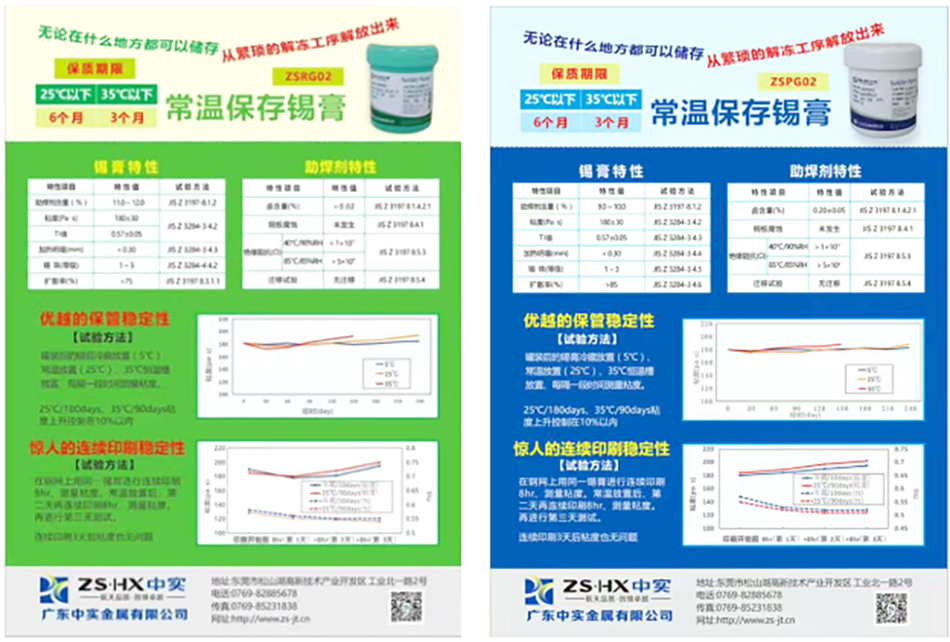

Medium solid metal bright products - stored solder paste at room temperature

Store the paste at room temperature - it allows you to "store anywhere and free yourself from tedious defrosting"

?

?

Guangdong Zhongshi Metal Co., LTD., high-tech enterprises, national aerospace and military units welding materials supplier. Founded in 1999, the company is headquartered in Songshan Lake High-tech Industrial Development Zone, Dongguan City, Guangdong Province. It is the only large-scale electronic solder material manufacturer entering the national high-tech zone, with a registered capital of 22 million yuan. It provides high-quality welding materials for aerospace, military and civil use. The main products of the company are: tin paste, tin powder, tin wire, tin strip, BGA tin ball, anode rod, flux, red glue and other electronic tin solder, with an annual production capacity of more than 6000 tons.