In the 1970s, with the rise of surface mount technology (SMT), solder paste came into being. At that time, China's related industries were still in their infancy. European, American and Japanese solder paste brands have taken advantage of the trend and occupied the solder paste application market. Until the turn of the century around the turn of the millennium, we gradually had our own brand of solder paste. Nowadays, the domestic solder paste industry has developed for many years, and the products are gradually mature.

?

?

With the domestic solder paste represented by Zhongshi brand, after years of technical precipitation, Zhongshi can provide customers with a variety of alloy solder paste, including lead-free solder paste, tin lead solder paste, halogen-free solder paste and other can be canned, or needle packaging solder paste products.

?

?

The high reliability, low void rate and good tin climbing performance of Zhongshi solder paste in practical application have been fully recognized by customers.

?

?

In order to meet the needs of customers' continuous innovation, "reducing the void rate to a greater extent and improving product reliability" has become the goal of Zhongshi solder paste product development.

?

?

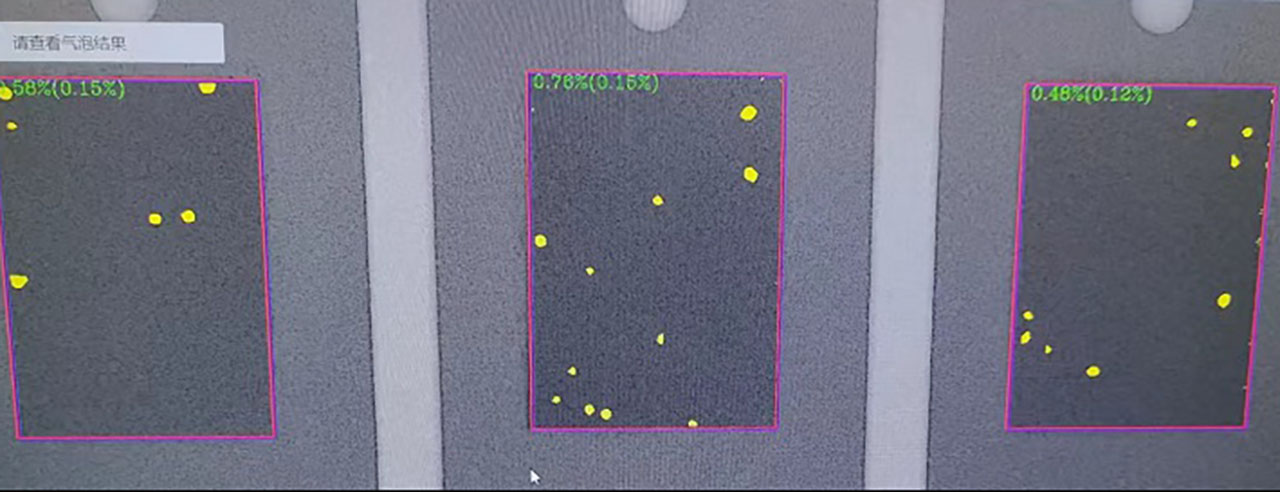

At the end of 2022, Zhongshi successfully independently developed a new ultra-low void rate solder paste: ZSRX01-RMB2. Recently, the solder paste in a well-known car company's semiconductor package sample performance is outstanding, the cavity rate is less than 1%, comparable to international brands, national brands in this field is another new breakthrough!

The above is part of the experimental data of Zhongshi ZSRX01-RMB2 < Welding conditions: vacuum reflow welding >

?

?

?

ZSRX01-RMB2 Product Features:

?

Very low cavity rate, to meet the needs of semiconductor and other precision components welding;

?

High reliability;

?

Excellent printability and printing life;

?

?

?

Effect of cavity rate on welding quality

?

One of the criteria to check the quality of welding is the hole rate of welding. When the "hole" size is large or its local density is too large, it will affect the mechanical properties of the welding layer and reduce the connection strength. At the same time, it will also reduce the thermal conductivity of the welding layer, resulting in local overheating of the device, causing failure.

?

?

?

Therefore, the void rate has an extremely important impact on the reliability of key electronic components.

?

?

?

?